Products PRODUCT DISPLAY

-

Gypsum block

Automatic gypsum block production line Gypsum block fixture Gypsum block drying kiln Simple gypsum block production line Small gypsum block production line -

Building gypsum

Natural building gypsum production line Hammer dryer calcination process Phosphogypsum treatment production line Desulfurization gypsum processing production line -

Plasterboard production line

Paper gypsum board production line -

Transportation equipment

- Electrical automation control system

-

Other Products

To undertake various types of mold and mechanical parts processing business Gypsum Mold Box / Hollow Floor Cover Machine

Products PRODUCT DISPLAY

Natural building gypsum production line

Product Details

Utilize natural gypsum raw materials

An annual output of 60,000 tons of construction gypsum production line program

First, the design basis

1. Environmental Protection Law of the People 's Republic of China (Revised in 1989);

2. Law of the People 's Republic of China on Prevention and Control of Atmospheric Pollution (revised in 2000);

3. Law of the People 's Republic of China on the Prevention and Control of Water Pollution (Revised in 2002);

4. Law of the People 's Republic of China on Noise Pollution Prevention and Control (1996);

5. Law of the People 's Republic of China on Prevention and Control of Environmental Pollution by Solid Wastes (2005);

6. Environmental Impact Assessment Law of the People 's Republic of China (September 2003);

7. "Cleaner Production Promotion Law of the People 's Republic of China" (2002);

8. "Integrated Emission Standards for Air Pollutants" (1996);

9. "Standard for Pollutant Emission of Boilers" (2001);

10. Decree No. 253 of the State Council of the People 's Republic of China on the Administration of Environmental Protection of Construction Projects, November 1998;

11. "Construction Project Environmental Protection Classification Management Catalog" (State Environmental Protection Bureau, Central [2001] No. 17);

12. Interim Measures for Public Participation in Environmental Impact Assessment (State Environmental Protection Administration, Central Development [2006] No. 28);

13. State Economic and Trade Commission and other six departments "on strengthening the work of industrial water conservation advice";

14. "Catalog of industries, products and technologies that are currently focused on encouraging the development of the country" (revised in 2000);

15. Catalog of Industrial Structure Adjustment (2005) (National Development and Reform Commission Order No. 40) December 2005.

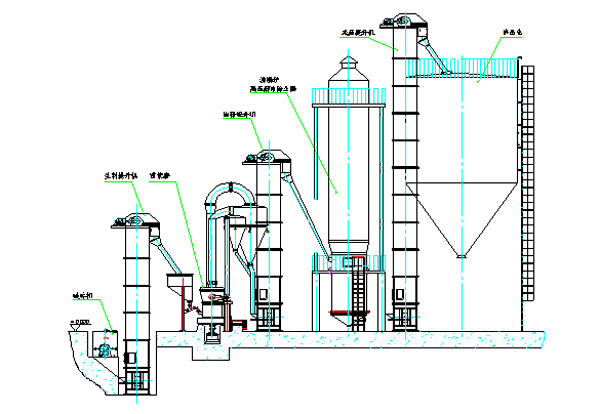

Second, the production process

1. Crusher will be large-size gypsum ore broken into less than 25mm small pieces of particles, after storage and transportation into the mill for grinding, the powder will be grinding to achieve the required fineness of the product gypsum powder The boiling furnace is calcined and the remainder is returned to the mill for re-grinding until qualified. After calcination, the qualified gypsum powder is fed into the clinker storage or used in the workshop.

Fourth, the production line equipment details

With an annual output of 60,000 tons of construction gypsum powder production line

Fifth, the electrical control system (optional) Electrical control system using the current advanced DCS (Distributed Control System), the choice of Japan's Mitsubishi PLC, will be scattered throughout the centralized control of the equipment. According to the control requirements, the Japanese Mitsubishi PLC, industrial computer and industrial configuration software (configuration king) as the alarm, monitoring and electrical control of the core part of the individual equipment according to process requirements for logical control and data acquisition module and communication module Will be collected to the equipment of the current, temperature, air volume uploaded to the host computer. The host computer will be sent to the parameters of the analysis and finishing, the overcurrent, overload, over temperature, low temperature and other abnormal display and alarm output. Data acquisition module acquisition crusher, Raymond Mill, blower, Roots blower and other high-power equipment, the current data uploaded to the PLC. Through the PLC and the host computer data exchange, in the host computer can monitor the above device current changes, when there is overcurrent, overload, phase loss, short circuit, etc., the alarm indicator flashes alarm and delay.

Communication module will be boiling furnace inlet oil temperature, feed powder temperature, export oil temperature, export powder temperature, furnace temperature and Roots blower air volume and other analog signals through 485 communication to upload to the host computer. In the host computer on the various parts of the temperature, air flow and the entire production line of the process of monitoring. In the silo equipped with material level sensor, the level sensor to the level signal into the PLC, when the material is too low or too high when the PLC can alert the police on duty, the production line into a unified as a whole. PC configuration software also has a data reporting function, you can reflect the production process of data, status, etc., and the data recorded. Which can reflect the production line real-time production situation, but also on the long-term production process statistics, analysis, so that production staff to real-time control and analysis of production, and can produce real-time statements and historical statements. Real-time and historical reports can be analyzed and printed. Excellent monitoring screen can make the management more relaxed, more perfect control, but also modern management of enterprise management tools. Through the monitoring screen can take the overall situation, to ensure product quality, but also timely detection of equipment failure and equipment operation. Report printing can count the consumption of raw materials and finished products, more convenient to manage the production.

Six, on-site staffing

Broken system 1 person

Heating system 1 person

Bagging staff 2 people

Machine repair 1 person

Total: 5 people

Seven, yield calculation

Taiwan when the production: ≥ 8.4 tons / hour (finished powder, 6 × 104 tons / year)

8, product-related parameters (GB9776-88 "building plaster")

1. Product quality: meet or exceed the national "building plaster" standard (GB9776-88) requirements.

Fineness: ≥ 80 mesh.

3. Flexural strength (with the raw material is directly related): ≥ 1.8Mpa; compressive strength: ≥ 3.0Mpa.

4. Main components:

Semi-water gypsum content: ≥ 80% adjustable

Dihydrate gypsum content: <5% adjustable

Soluble anhydrous gypsum content: <5% adjustable

5. Initial setting time: 3 ~ 8min adjustable; final setting time: 6 ~ 15min adjustable.

6. Standard thick: 78 ~ 85% adjustable.

Nine, energy consumption

Power consumption: ≤ 30KWH / t finished powder (this value is based on installed capacity calculation, the production should be reduced in practice).

Ten, site requirements (not including raw material yard)

40 meters × 22 meters

Product Parameters

Unique advantages

Third, the boiling furnace process introducedWith the gypsum industry development and progress, all walks of life on the demand for gypsum powder is also growing, the quality requirements of gypsum powder is also getting higher and higher, gypsum powder manufacturing process is also progress, in the gypsum powder Production and processing links in the drying and dehydration is the key link, but also the most difficult to grasp the part, according to this situation we have years of gypsum powder production and deep processing industry continue to explore and research, developed a new generation for a variety of gypsum powder production Requirements of the dehydration equipment - boiling furnace. 1. Working principle Boiler furnace drying system Main working principle: Boiler main body mainly by the small diameter of the heat pipe composed of coil, coil into the heat transfer oil, after heat transfer, the heat released to the furnace inside. The bottom of the boiling furnace installed Roots blower, through the wind board to the cold wind into the furnace, blowing the furnace powder to the boiling state, at a certain temperature, after drying off the crystal water powder, the quality becomes light, automatic Flow to the discharge port, so that the output of gypsum powder quality and stability, the crystallization of water content, the first finish time is relatively easy to control. In addition, the equipment using dry electrostatic precipitator dust, dust removal efficiency of 95% or more, eliminating the dust pollution.

2. Simple structure, easy to damage

As the material to achieve fluidization, the furnace does not need to have rotating parts, the structure of the furnace is much simpler. Not only easy to manufacture, almost no need to put into operation after the maintenance. Due to the use of low-temperature heat source, the furnace in any case have not been burned out of danger, equipment life is particularly long.

3. Equipment is compact, small floor furnace is a vertical arrangement of the equipment, dust collector set in the furnace above, with the furnace into a whole, the equipment is very compact. Not only occupy less, but also to avoid dust condensate condensation.

4. Low energy consumption Boiler heat consumption and power consumption are low. Thermal energy: heat from the heat source to the material, in addition to a small part for the heating of the bottom of the furnace into the cold air and a small amount of furnace heat loss, almost all effective for the decomposition of the material dehydration. The thermal efficiency of the furnace itself is above 95%. Of course the boiling furnace uses a secondary heat source, and the final thermal efficiency also multiplies the thermal efficiency of the furnace by the thermal efficiency of the boiler. But the steam boiler or hot oil boiler are very mature thermal equipment, the thermal efficiency is relatively high. Steam boilers can generally reach 60-70%, hot oil boiler can reach 70-80% (my company plans to use organic heat carrier thermal oil furnace). So the total thermal efficiency of the boiling furnace is relatively high, the use of steam, up to 57-67%; using hot oil, up to 67-76%. General thermal calcination equipment, although the direct use of a heat source, but the thermal efficiency is rarely more than 50%. Domestic heating furnace heat consumption target of 7.7 × 105KJ / t building gypsum. Power: the boiling furnace does not need to turn, there is no mixer, the material is mainly by the gypsum dehydration of water vapor to achieve fluidization, the need to drum in the bottom of the air is also very limited, so the blower power is very small, so The energy consumption of the boiling furnace is much less than that of the conventional calcining equipment.

5. Product quality is good, the composition of the plaster composition is ideal, the physical properties of stability due to the use of low-temperature heat source, gypsum is not easy to burn, as long as the control of the expected temperature, the finished product does not contain dihydrate gypsum, anhydrous gypsum is only 5% , The rest are semi-water gypsum. This composition is ideal, physical performance is also very stable. In order to meet the above requirements of production equipment, after my company research and development developed a set of boiling furnace equipment production and processing technology, the main materials are selected high-quality steel. (GB3087-82); steel plate with carbon steel and low alloy steel plate (GB713-86); frame steel are used GB products. In addition, in the welding process, in order to ensure the quality of welding operators are holders of certificates, welding is completed, in order to prevent leakage of heat oil, the main coil for hydraulic test, water pressure test to 1.0 ~ 1.5MPa and pressure for more than 24 hours No leakage is the product qualified. The following are the same as the "

Customization process

2. Flow chart

Order online

In order to be able to contact you in a timely manner, please be sure to fill out your contact information and demand information, you can enter your needs, such as the type of raw materials, capacity, feed size, the final product size, etc .; you can also QQ Contact our 24-hour online customer service, the ability to electromechanical - to become your satisfaction with the partners.